Economic Impact of IoT in The Oil and Gas Industry

Oil and gas companies are excited about the possibilities provided by the Internet of Things (IoT) in the oil and gas industry as it relates to improving operations and bringing economic benefits. Studies show that by 2025, IoT could make a significant contribution to the global economy, ranging between $3.9 trillion and $11.1 trillion. This anticipated impact is reflected in the exponential growth expected for the global IoT market within the oil and gas sector, with estimates reaching nearly $40 billion by 2023, according to insights from BIS Research.

The oil and gas industry’s response to this wave of innovation is evident, as many companies within the sector are already capitalizing on IoT in the oil and gas industry applications. Surveys conducted by authoritative sources like 451 Research’s Voice of the Enterprise Survey have revealed that a substantial portion of oil and gas enterprises are actively incorporating IoT into their operations. Furthermore, an impressive 20% of surveyed participants have expressed intentions to seamlessly integrate IoT technologies into their workflow processes in the immediate future. This dynamic progress not only positions the sector at the forefront of innovation but also foresees a potential economic impact of up to $930 billion over the forthcoming decade.

The Internet of Things (IoT) in the oil and gas industry is revolutionizing the sector with remarkable swiftness. industry experts projecting that IoT solutions could eliminate unplanned well outages, boost crude output by 10 percent over a two-year period, and increase profits by nearly $1 billion for large O&G companies. This anticipated impact is further substantiated by predictions that IoT applications within this industry could contribute as much as 0.8% to the GDP, equivalent to a staggering $816 billion augmentation over the forthcoming decade. The scale of possibilities is undeniable, motivating a significant 62% of oil and gas executives to actively devise digital strategies aimed at reshaping their business landscape.

In other words, while implementing new tech requires time and capital, investing in IoT in the oil and gas industry can offer a tremendous return on investment (ROI). To help you make a case for building a more connected environment — and prepare for this unstoppable industry transition.

In this article, we explore the transformative impact of IoT in the oil and gas industry, showcasing how companies can leverage smart technologies to thrive and outperform in an ever-competitive landscape.

What is the Internet of Things, exactly?

IoT is a term used to describe an ever-expanding network of internet-connected devices and systems that can communicate data in real time, without human involvement.

A good example of IoT is Smart Home devices, like thermostats that communicate energy usage data to your mobile phone through an app, or light bulbs that automatically adjust brightness levels depending on the time of day.

In the oil and gas industry, IoT takes the form of sensors that monitor inventory levels and pump performance and allow you to automate various tasks — such as dispatching trucks when an onshore tank needs to be emptied.

The Role of IoT in Oil and Gas Industry

Undeniably, the oil and gas industry serves as a lifeline for the global economy, powering key sectors such as transportation, electricity generation, heating, and manufacturing. However, the industry has its share of challenges, including dealing with aging equipment and legacy systems, hazardous environments, stricter regulations, and geopolitical issues that hinder long-term business predictions. To overcome these challenges, businesses adopt advanced technologies, including the Internet of Things (IoT).

IoT in the oil and gas industry involves implementing interconnected devices, sensors, and systems. It enables data collection, communication, and analysis across sectorial operations. It would include integrating digital technologies with physical assets and infrastructure that help enhance operational efficiency, safety, and decision-making, The IoT in the oil and gas industry is like having eyes everywhere.

In the oil and gas industry, IoT devices and sensors are strategically placed throughout the production, transportation, and distribution processes. Their role is to collect and transmit crucial data. This collected data is then subjected to in-depth analysis using advanced analytics and sophisticated machine learning algorithms. The goal is to extract meaningful insights that enable informed decision-making. The information derived from this analysis can be employed for various purposes, including predicting maintenance needs, identifying anomalies early on, optimizing production workflows, enhancing safety protocols, and minimizing instances of downtime. Ultimately, this comprehensive approach contributes to the safety and efficiency of operations while benefiting all involved stakeholders.

Benefits of IoT in The Oil and Gas Industry

By leveraging advanced technologies of the Internet of Things in the Oil & Gas sector, companies are unlocking unprecedented opportunities like:

- Increased Revenue

In recent years, reduced oil prices have increased competition between oil and gas companies — and many organizations are seeking strategies to help tighten margins and improve their bottom line. But focusing solely on short-term cost-cutting measures could stifle long-term business success. Investing in IoT in the oil and gas industry will ensure companies are more strategic in their cost reduction by helping pinpoint inefficiencies, improve the accuracy of demand predictions and streamline expensive processes. - Enhanced Operational Efficiency

In the oil and gas industry, equipment failures span a range from causing annoyance to evolving into truly catastrophic scenarios. As downtime increases, so do financial losses. Furthermore, the impending shortage of skilled personnel make this challenge even worse.However, IoT sensors is well-poised to overcome these obstacles. By implementing a network of sensors, professionals gain greater visibility into equipment performance, eliminating the need to send teams to the field for assessment. This dynamic approach enables swift repair or replacement of equipment at the earliest indication of issues, effectively reducing or even eliminating unplanned outages. - Improved Decision-Making

Being a technology expert in the energy sector, you have consistently relied on data to shape your decision-making. The effectiveness of your senior leadership team’s decision-making and their capacity to steer success hinges on the caliber of the information they are provided.Rather than depending on approximations and best guesses to guide your drilling strategy, the Internet of Things (IoT) in the oil and gas industry offers you a continuous stream of real-time data. This becomes particularly powerful when you combine your sensor network with a dependable IIoT (industrial internet of things) platform. Having access to these advanced analytics could help oil and gas organizations quickly advance production and outpace competitors. - Reduced Safety Hazards

Oil rig personnel encounter a range of hazards, some of which can be life-threatening. IoT technologies play a crucial role in swiftly identifying potential dangers, such as gas leaks or equipment malfunctions. This enables rapid intervention and reduces the potential risks to both individuals and the environment. IoT allows you to remotely troubleshoot issues, enhance proactive maintenance procedures, and ultimately helps companies avoid the necessity of sending workers into dangerous situations. In simpler terms, by implementing IoT in the oil and gas industry can, quite literally, save lives. - Decreases Environmental Impact

It’s no secret oil drilling and production have considerable environmental impacts, and numerous energy companies are actively searching for solutions to minimize their ecological footprint.

Leveraging IoT in the oil and gas industry allows companies to decrease the risks of oil spills, reduce carbon emissions, and make their operations more efficient.

- Reduced maintenance costs:

By the help of IoT data, predictive maintenance can spot possible problems before they become serious, stopping expensive downtime and making equipment last longer. - Advanced analytics:

Data generated by IoT can be analyzed using advanced methods like algorithms and machine learning. This helps to find patterns, trends, and unusual occurrences, which in turn leads to making things work better and more efficiently.

Optimize Inventory Levels Based on Actual Usage

IoT greatly improves how oil and gas managers manage their inventory. It offers a faster, easier, and more efficient method for handling large stocks of petroleum. Furthermore, by incorporating smart IoT solutions, managers can establish priorities and thresholds. If these thresholds are surpassed, instant notifications are triggered, prompting specific actions. This real-time response can occur even during ongoing processes, highlighting the remarkable potential of IoT in the oil and gas industry for comprehensive industrial automation.

Improve Stockroom Management

Deploying sensors and devices for efficient industrial operations helps companies gather valuable data, leading to better insights for maximizing business benefits. The increased use of sensor-equipped machines available online allows O&G companies to potentially reduce capital costs by up to 20%. Collecting data from sensors enhances reliability, efficiency, and creates new value from unexpected positive interruptions.

Real-Time Monitoring

Offshore oil and gas production is tricky and unsafe. Because offshore platforms are far away and isolated, it’s hard for oil and gas companies to know exactly what’s happening with their production. This means they often don’t realize when machines or processes are going wrong, which can lead to equipment breaking and costly downtime. In some cases, not keeping a close eye on things can even cause big explosions that hurt the environment, workers’ lives, and the reputation of the companies.

Luckily, the Internet of Things (IoT) in the oil and gas industry and better ways of connecting things can now help monitor offshore operations more reliably and effectively. They use special devices and smart connections to provide real-time montoring updates to managers, so they can quickly and smartly make decisions based on the latest information.

Removing Manual Measuring Processes

Automated processes through IoT almost remove the excess involvement of manual labor and reduce the chances of causing errors in results. It involves using automated and semi-automatic machines instead of individuals to drill, inspect and maintain equipment in high-risk offshore or off-site operating environments, drilling and manufacturing.

Challenges in the Oil and Gas industry

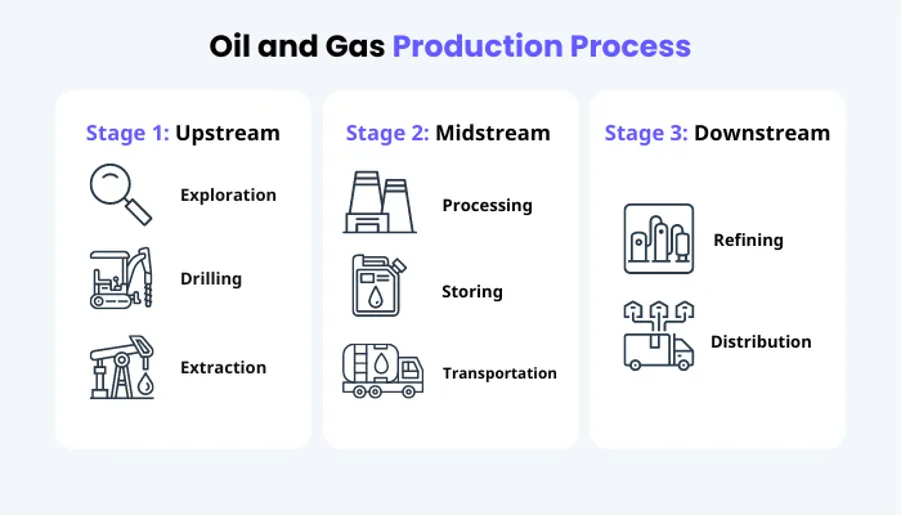

Oil and gas (O&G) companies are divided into three primary categories: upstream, midstream, and downstream.

- Upstream Companies: These companies focus on exploring new oil and gas reservoirs both on land and at sea.

- Midstream Companies: They handle the logistics part, like managing vehicle fleets that transport O&G products to storage sites, retailers, and refineries.

- Downstream Companies: These are involved in marketing, refining, and distributing O&G products. Gas stations are an example of downstream O&G businesses.

Naturally, the challenges these companies face vary, and the changes that occur with the integration of IoT in the oil and gas industry also differ accordingly.

In conclusion

The integration of IoT in the oil and gas industry is not just a trend but a necessity for future success. Companies that embrace IoT technologies will enhance operational efficiency, improve safety, and achieve significant economic gains.